Lobsterfish NV, based in Deerlijk, has been a specialized wholesaler of lobsters and other shellfish since 1997, serving the hospitality industry, retailers, and private customers through their webshop. They also offer company visits, tastings, and events, including seafood platters provided by “The Oyster Crew.”

Roterijstraat 20

8540 Deerlijk

The challenge

At Lobster Fish NV, a specialized wholesaler of lobsters, fish, and delicacies based in Deerlijk, numerous pallets are prepared daily for delivery to customers in the hospitality and retail sectors. These pallets are wrapped in a cold, wet, and salty environment—typical of shellfish processing. The humid conditions, combined with the salt content in the air and on the floor, present a significant challenge for both equipment and staff. Until recently, pallet wrapping was done manually, resulting in inconsistent load stability and physical strain on employees. Moreover, manual operations under these conditions posed risks to the continuity and safety of the logistics process.

Solution

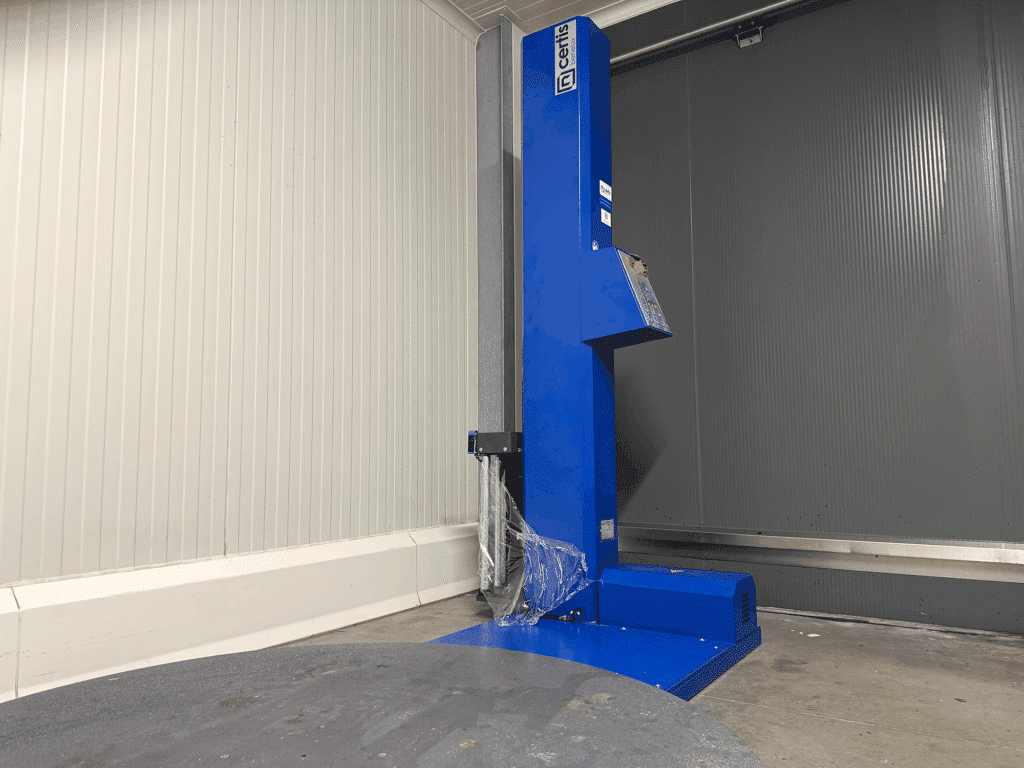

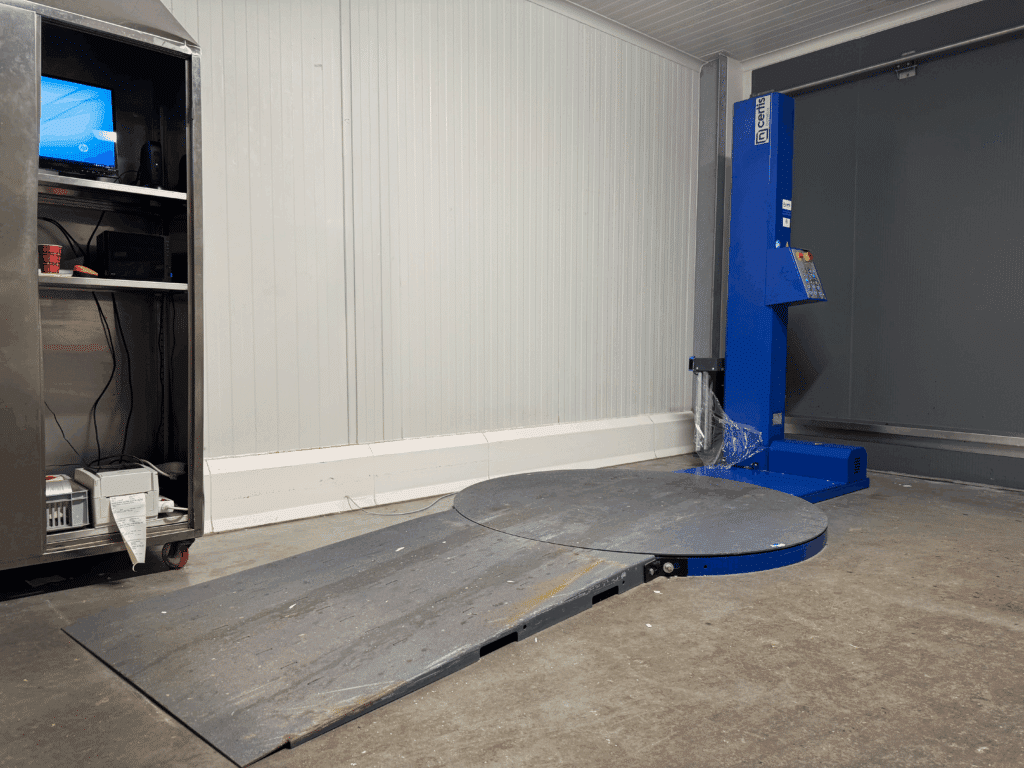

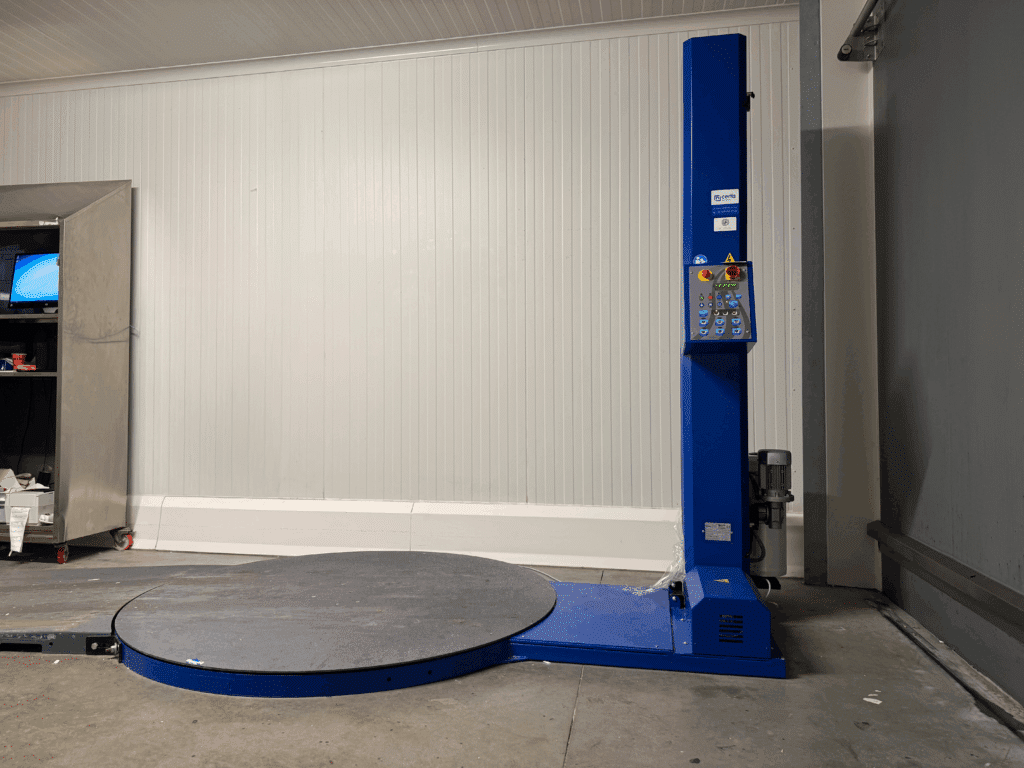

To optimize their packaging process, Lobster Fish NV chose a Tablo 1000 pallet wrapper. This semi-automatic machine was equipped with an extra-long ramp, allowing easy use of pallet trucks even in limited space or on slippery surfaces. Given the salty and wet conditions in the packaging area, a locked stretch film was selected. This film offers enhanced strength and high stretch resistance, ensuring reliable load stability—even under fluctuating temperatures or humidity. The combination of the right machine setup and suitable film makes the system resistant to the specific challenges of the cold seafood environment.

Result

Thanks to the new pallet wrapper, Lobster Fish NV now benefits from perfectly and consistently wrapped pallets, with significantly improved load stability during transport and storage. The loads now meet the highest safety standards, eliminating damage or shifting during transit. Moreover, automation has greatly improved ergonomics: employees no longer need to perform heavy manual tasks, enhancing both comfort and safety. The combination of more efficient packaging, increased safety, and reduced physical strain ensures a smooth workflow—and a satisfied customer. Lobster Fish is now better equipped to deliver their fresh products to customers in top condition.