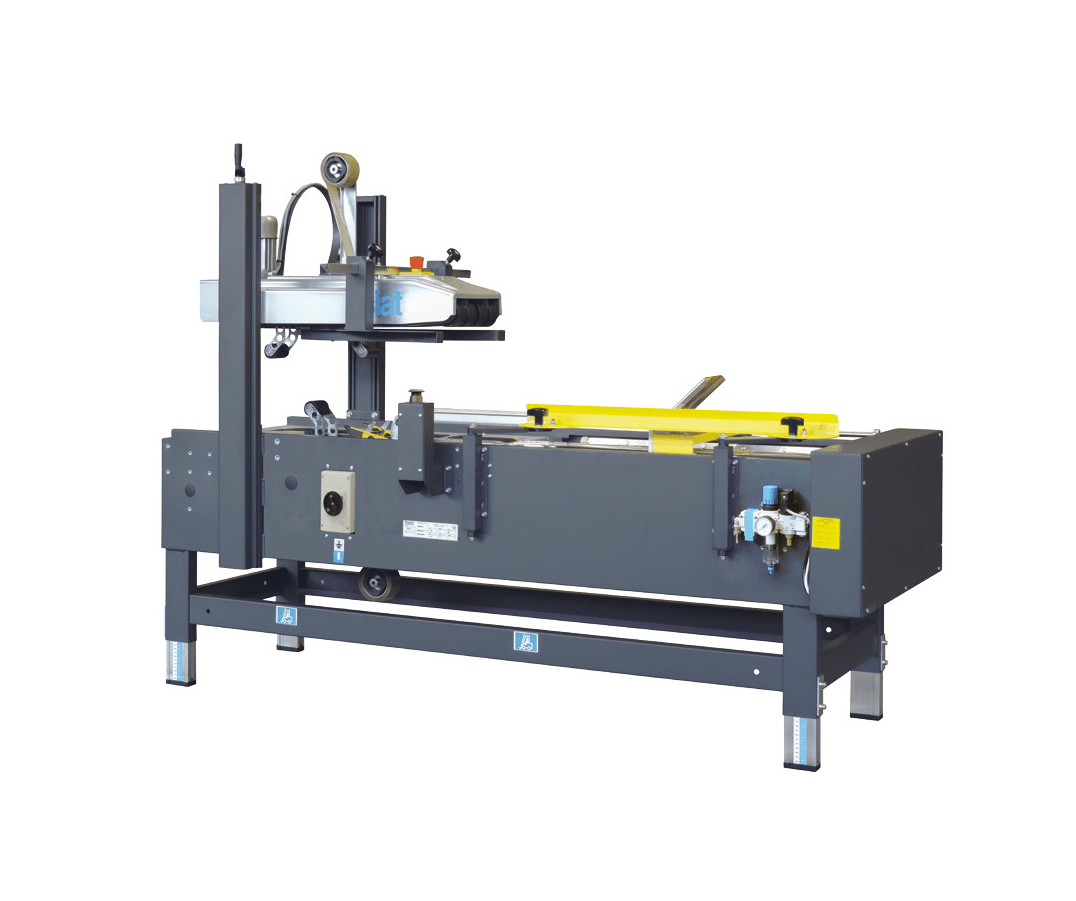

Semi-Automatic Single Block Case Former & Sealer PS50-TB

Semi-Automatic Single Block Case Former & Sealer

Semi-Automatic Case Erector F105

Semi-Automatic Case Erector

Don't know which product you need?

The Role of Tape Carton Sealers in the Packaging Industry

- Efficiency and Speed:

Tape carton sealers significantly increase packaging speed. Unlike manual taping, these machines can process a large number of boxes in a short amount of time, which is crucial for businesses with high production output. - Uniformity and Quality:

These machines ensure consistent and uniform tape application. This not only improves the aesthetics of the packaging but also guarantees that each box is sealed in the same way, contributing to product safety during transport. - Cost Savings:

Although the initial investment for a tape carton sealer can be significant, businesses save on labor costs in the long run. Additionally, the use of standardized tape quantities per box reduces material costs.

Types of Tape Carton Sealers

- Semi-Automatic Tape Carton Sealers:

Ideal for smaller operations. The operator manually feeds the boxes through the machine, which then automatically seals them. - Fully Automatic Tape Carton Sealers:

Suitable for large-scale operations. These machines fully integrate with production lines, where the boxes are automatically fed, sealed, and conveyed.

Innovations and Trends

- Integration with IoT:

Some modern tape carton sealers are equipped with IoT technologies, allowing them to communicate with other machines and management systems within the production line. - Sustainability:

There is a growing trend towards the use of environmentally friendly tape and materials, as well as more energy-efficient machines. - Adaptability:

New models offer more flexibility in terms of box sizes and tape types, making them suitable for a wider range of products.

Conclusion

The evolution of tape carton sealers in the transportation and packaging industry underscores the ongoing pursuit of efficiency, cost savings, and quality improvement. With the emergence of new technologies and sustainability initiatives, these machines remain an indispensable part of modern packaging and distribution processes.